|

|

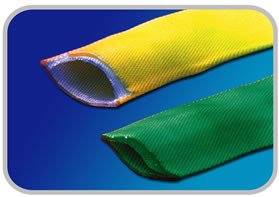

WEAR PROTECTION

The number one

cause of synthetic sling failure is cutting. When slings are cut, property

damage and personal injury or death can result. Wear pads can help to

reduce this problem by acting as a buffer between the load edge and the

sling.

Used with steel slings, wear pads help protect both sling and load from

damage along points of contact.

Features, Advantages and

Benefits

- Promotes Safety

- Helps prevent sling

cutting that can cause property damage, personal injury or death.

- Saves Money

- Protects both sling

and load from damage

- Increases sling

life

Inspection of Wear

Pads

If pad is damaged, the

sling may also be damaged. Inspect both thoroughly and check slings for:

- Visible red core

warning yarns

- Cuts on the face or

edge of webbing

- Holes, tears, snags

or crushed web

- Signs of excessive

abrasive wear

- Broken or worn

threads in the stitch patterns

Safe Operating

Practices

The sliding of slings

along a load edge is a major cause of cutting. Loads must be rigged to

prevent this. We recommends that, prior to making a lift, the load be

raised slightly, then lowered so that the wear pads can be inspected for

damage. If pads show evidence of cutting, the lift should be tested again

using different pad material.

While ordering with

Round Slings, remember to confirm if you need Single Leg or Double Leg

Sling Cover on your Sling.

We shall be always

pleased to assist you for selection of suitable Wear Protection covers for

your slings to save your slings from damage. |